is the torsion test vs sheer force loading test|high strain rate shear testing : wholesaler The torsion test is improper for determining failure strains, because the failure initiation can depend on the surface quality. Specimens with rougher surfaces are prone to shear failure 10 de dez. de 2023 · Ficha Técnica: Barcelona x Girona . Competição: Campeonato Espanhol; Jogo: Barcelona x Girona; Jogo Ao Vivo: ESPN e Star+; Fase/Rodada: .

{plog:ftitle_list}

11 de ago. de 2023 · Andressa Urach gravou, nesta sexta-feira (11), novos conteúdos para suas plaformas adultas. A modelo, de 35 anos de idade, alugou um quarto de motel para ser filmada por seu filho, Arthur Urach .

what is torsional testing

What is the difference between torsion test and tension test? A torsion test applies twisting forces, examining shear properties, while a tension test applies pulling forces, studying tensile properties like elongation and tensile strength. .The torsion test is improper for determining failure strains, because the failure initiation can depend on the surface quality. Specimens with rougher surfaces are prone to shear failureTorsion Shear Test: This test involves applying a twisting force to a material until it fails. It’s useful for materials and components like shafts and fasteners that experience torsional stresses in their applications.While there are many different loading conditions that must be analyzed, this lab focuses on the shear strain and angle of twist of an aluminum shaft when a torque is applied. With this .

Figure2:(a)Normaland(b)shearingdeformations. NowconsiderthecaseillustratedinFig.2(b),inwhichtheloadPisappliedtransversely to thespecimen . The purpose of torsion testing is to analyze the mechanical behavior of a material when subjected to twisting forces. It helps determine the material's shear .

internal vapor analyzer

In particular, the results from the torsion test will be compared to the results of the engineering tensile test for a particular alloy using the effective stress-effective strain concept.When compared to experimental shear yield strengths, common metals are 1000 to 10,000 times weaker than theory predicts. Theoretical Shear Strength, τ TH ≈G/2π to ≈G/30 depending on .This article reviews the common methods of shear and multiaxial testing for the evaluation of engineering components such as fasteners and mill products. It discusses shear test .Figure2:(a)Normaland(b)shearingdeformations. NowconsiderthecaseillustratedinFig.2(b),inwhichtheloadPisappliedtransversely to thespecimen .

Mam Tor road destroyed by subsidence and shear, near Castleton, Derbyshire.. In engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shear.A shear load is a force that tends to produce a sliding failure on a material along a plane that is parallel to the direction of the force. Torsional Shear Test: In this method, torque is applied to cylindrical specimens until they fail under shear. This test can be used specifically for determining Torsion shear characteristics such as: Shear .

Torsion tests twist a material or test component to a specified degree, with a specified force, or until the material fails in torsion. The twisting force of a torsion test is applied to the test sample by anchoring one end so that it cannot move or rotate and applying a moment to the other end so that the sample is rotated about its axis.Torsional shear stress solved examples: 1] The shaft of the motor is rotating with a maximum torque of 6 N.m. If the shaft has a diameter of 25 mm, find the maximum shear stress acting onto the shaft. Given: T = 3 N.m d = 25 mm = 0.025 m. Solution: The maximum shear stress acting on the solid circular shaft is given by,developed by applying a force of F via load handle above the system thru a distance spindle arm. . the torsion test specimen will be twisted to failure in order to determine the shear stress at the limit of proportionality. The shear stress at the limit of proportionality is the largest value of the shear stress for which the material will .For the solid cross-section shaft with material homogeneity on the cross-section, the both the shear strain and shear stress vary linearly with radial position on the cross-section, as shown below. Stress element for points on the cross-section For point "a" on the cross-section, the shear stress on the x-face points in the positive z-direction.

The final characteristics acquired after the torsion test include Modulus of Rigidity, maximum Shear Stress, maximum Torque, and Angle of Twist, and how the material responses in each case, are .

Direct shear tests measure a material's shear strength by applying a shear force directly along a predefined plane within the test specimen. These are the 3 most common types of shear tests: Single shear tests involve samples that are clamped .

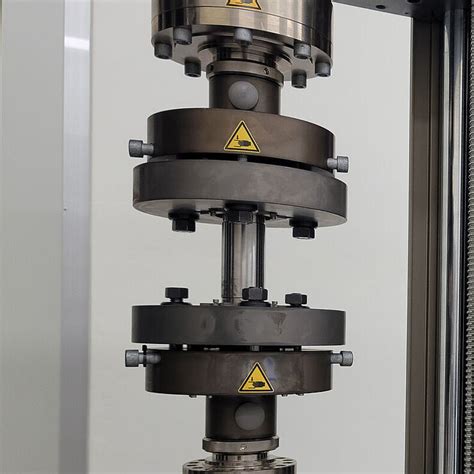

The torsion test is a mechanical test method used to examine the deformation of a specimen through a twisting/rotating motion.. Torsion, in its simplest form, is the action of twisting. Many everyday materials, components, component assemblies, and end-user products used in various industries are designed with the primary purpose of supporting this direction of movement. The upper surface will shear by an angle \(\alpha\) corresponding to a horizontal displacement \(\delta x\) The geometry of the shearing action is shown in Figure 26.5. Figure 26.5: Shearing forces. The shear stress is defined to be the ratio of the tangential force to the cross sectional area of the surface upon which it acts,What was the effective stress during the torsion test? During the torsion test the only stress applied was the true shear stress, τxy ~ . No other stresses were present during the torsion test: 0~ = ~ = ~ = ~ = ~ = σx σy σz τyz τzx Substituting these conditions into Eq (7), we find: σ= 3 τ~ xy.. during the torsion test the effective .

torsion testing systems

One of the most common examples of torsion in engineering design is the power generated by transmission shafts. We can quickly understand how twist generates power just by doing a simple dimensional analysis.Power is measured in the unit of Watts [W], and 1 W = 1 N m s-1.At the outset of this section, we noted that torque was a twisting couple, which means that it has . 2.1 Torsion test method. The torsion test method is a mechanical testing technique used to evaluate shear modulus (G) of materials, including timber. The proposed version of CEN standards provide guidelines for conducting the torsion test on timber. This method involves subjecting a test specimen to a torque along its longitudinal axis, which .

Torque on a shaft is the main cause of shear stress. The torsion induced when torque is applied to a shaft causes a distribution of stress over the shaft’s cross-sectional area. . Performing a torsion test is a crucial process in materials testing, helping engineers and scientists understand a material’s response to twisting forces .Shear Strain: Dr. M. Medraj 4 Torsion Test • Not as common in testing as tensile test. • Torsion test samples (similar to tensile samples). • But also used on full sized parts such as shafts, axles, drills etc. Troptometer Torsion machine • Torsion machines use an electrical motor and gear drive to apply a torque to the specimen Understanding Torsion TestingIn the field of mechanics and materials science, torsion testing is a crucial method for assessing the strength and behavior of materials under twisting forces. This comprehensive guide will provide an in-depth understanding of torsional testing, the machines used, and their applications in evaluating the performance and reliability . Load, Shear Force, and Bending Moment Relationship. Referring to figure 5 let us consider a short length ‘\( \delta x \)’ of a beam at a distance ‘x’. Fig 5: Load, Shear Force, and Bending Moment Relationship. Let ‘w’ be the load per unit length acting vertically downward over this short length. The shearing force will rise from .

As we learned while creating shear and moment diagrams, there is a shear force and a bending moment acting along the length of a beam experiencing a transverse load. In a previous lesson, we have learned about how a bending moment causes a normal stress.This normal stress often dominates the design criteria for beam strength, but as beams become short and thick, a .• Ductile materials have a shear strength about one-half of tensile strength. • Brittle materials have a shear strength which can be greater than their tensile strength. Failure line Uniaxial tensile test Uniaxial compression test Torsion test s t In the compression region, the material’s resistance to shear increases 19.5 Coulomb-Mohr .

The Axial-Torsion Test (biaxial test) using an Axial-Torsion Test Machine provides a comprehensive set of data that can be analyzed to understand material behavior under combined axial and torsional loading. Here’s a list of the common data obtained during this test: Axial Data: Axial Load: The force applied along the length of the specimen.

In this video we will explore torsion, which is the twisting of an object caused by a moment. It is a type of deformation. A moment which tends to cause twis. Recently, a shear test using the in-plane torsion kinematics was also suggested by Brosius et al. (2011): the so-called twin bridge shear test. In the remainder of this paper, we focus on three approaches for shear testing: the Miyauchi shear test, the shear test according to ASTM B831 and the twin bridge shear test using in-plane torsion.

A torsion test has the following advantages over the tension test. A shear stress–strain diagram determined from torsion test is fundamentally more important in characterizing the plastic behaviour of material than a conventional or a true stress–strain curve obtained from tension test. 3.5 Processing of shear test data. After cutting the specimen, record the maximum test force (F) during the shear test. Calculate the shear strength (τb) in MPa using the following formula: Single shear strength: τb=F/S 0 (S 0 — original cross-sectional area of the sample, mm 2)The material will undergo an angular deformation, and the ratio of the tangential force per unit area to the resulting angular deformation is called the shear modulus or the rigidity modulus. . Shear Modulus and Torsion Constant is shared under a .

torsion testing machine

Torsion tests can be carried out with just a rotational motion or with both axial and torsional forces applied. The types of torsion tests: failure, proof, and operational. A proof test is a process for examining material for a set period while subjected to a certain torque force.

torsion testing definition

Flight history for DKFMF. Flightradar24 is the best live flight tracker that shows air traffic in real time. Best coverage and cool features!

is the torsion test vs sheer force loading test|high strain rate shear testing